Did you know that NASA uses vacuum chambers to make their rockets? Now you do. And this tool can help your industry thrive too.

In this article, you’ll learn about the product and all you need to know before you buy vacuum chambers for sale. You’ll also know industries using this machine, what to expect and how to choose the best one for your needs. Read on to find out more.

First…

What is a Vacuum Chamber?

As the name suggests, a vacuum chamber works by removing air and pressure from spacious confinement. Manufacturers use the appliance to test the durability and quality of their products. A pump helps create those conditions, thus providing the benefits.

Engineers and electricians can thus reduce losses by testing how commodities perform in real life. For example, cargo companies can gauge the stability of various packages whose destination requires air travel.

Other industries can also use the chamber to dry or off-gas parts. Thus, customers can know product restrictions through the data from the vacuum chambers. This protocol thus promotes quality improvements and safety among users.

So…

What Industries Use Vacuum Chambers?

Electronic Manufacturers

Circuit boards, phones, and watches are examples of electronics sensitive to moisture. So, engineers use the vacuum chamber to dry those items. This procedure thus helps fix defective components or foster the delivery of quality products, enhancing a company’s sturdy reputation.

Some electronic components are also fragile and prone to heat destruction. But the vacuum chamber helps dry those parts while preserving their utility.

Aerospace Industry

Aerospace is a high-risk market. Therefore, engineers must be careful with each part to ensure safety and optimal performance. And a lack of that standard would lead to catastrophic accidents. Besides, how else would you be comfortable with air travel?

Aeronautical and space companies test small parts such as screws, bolts, switches, and latches. You’ll also find larger vacuum chambers testing door handles, seat cushions, and other fibrous materials; manufacturers examine those parts multiple times to ensure precision.

Air travel uses heavy-duty and spacious vacuum chambers. For example, a typical machine measures seven by 12 meters and handles a -180C – 100C temperature range. Those conditions thus simulate the extreme conditions that airplanes must endure, allowing modification.

Food and Beverage Industry

Quality assurance is a critical standard for foods and beverages. You risk degrading your meal’s taste, appearance, and smell without proper storage measures. Or worse, you risk poisoning your customers, resulting in lawsuits and massive business losses.

So, what’s the solution? Companies can use vacuum chambers to hasten the cooling process while transporting foods. The machine also prevents the growth of mold, bacteria, and other contaminants. You’ll thus provide quality, tasty, flavorful food and foster business growth.

Biopharmaceutical and Chemical Industries

Pharmaceutical companies require accurate information before stating various drugs’ expiry dates and storage conditions. A lack of that standard would lead to drug-induced toxicity, ineffective compounds, or cut usage time. Scrupulous companies thus avoid those glitches.

How? Manufacturers use vacuum chambers to crystallize, degas, dry, cool, or sterilize equipment and formulations.

The biological sciences also benefit when the machine helps them prevent specimen degradation. Research and treatment modalities thus progress.

Chemical producers use the appliance to make commodities like polyurethane, distill extracts or perform polycondensation. Moreover, those scientists preserve some chemicals that deteriorate fast in the heat. And what better quality option is there than the vacuum chamber?

The device reduces a sample’s thermal load while providing enough heat for those procedures.

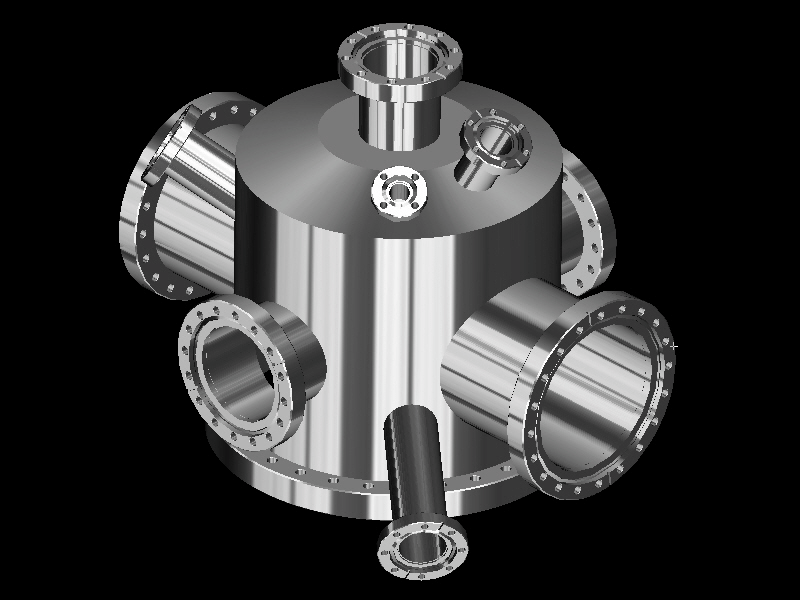

The Design of Vacuum Chambers

You’ll want to work with a vacuum chamber that fosters stress-free, consistent, and quality operations. Therefore, the design materials should withstand the pressure and heat from the machine. Also, consider the chamber’s shape, control protocols, and protective mechanisms.

Here’s each feature in detail.

Materials

Manufacturers use steel alloy and stainless steel metals to make vacuum chambers. Why? Because those materials are chemical, rust, corrosion, heat, and pressure resistant. Hence, your industry and laboratory will have incomparable durability and safety.

Control Protocol

The best vacuum chamber gives you an effortless time when processing your load. Luckily, technology has improved, allowing you to monitor your operations from afar. These automation systems thus require you to input your temperature and pressure preferences, and that’s it.

Protective Mechanisms

Quality vacuum chambers come with safety alarms, gauges, and valves. Those parts promote sample quality preservation and prevent accidents.

Conclusion

Vacuum chambers help many industries adhere to strict quality and regulation standards. The machine allows you to dry, sterilize and test equipment during production. Choose an automatic and high-quality machine with protective features for the best experience.

Writer’s bio: Nikolay Stoyanov and his CBDadvertising.agency provide high-quality hemp content marketing services for CBD brands in the United States since 2015.